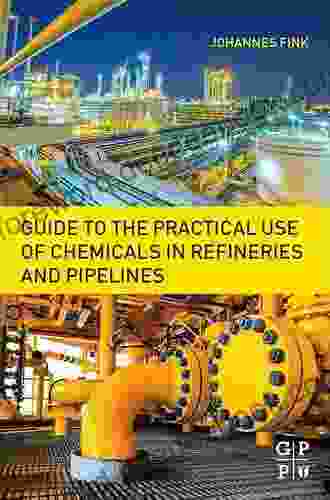

A Guide To The Practical Use Of Chemicals In Refineries And Pipelines

Chemicals play a vital role in the operation of refineries and pipelines. They are used for a variety of purposes, including corrosion inhibition, scale prevention, water treatment, fuel additives, demulsification, and surfactant applications.

4 out of 5

| Language | : | English |

| File size | : | 6542 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 240 pages |

This guide provides an in-depth look at the practical applications of chemicals in refineries and pipelines. It covers the different types of chemicals used, their functions, and how they are applied.

Corrosion Inhibition

Corrosion is a major problem in refineries and pipelines. It can lead to leaks, equipment failure, and even explosions. Chemicals are used to inhibit corrosion by forming a protective layer on metal surfaces.

There are a variety of different corrosion inhibitors available, each with its own advantages and disadvantages. The most common type of corrosion inhibitor is a film-forming inhibitor. These inhibitors work by forming a thin layer of organic material on the metal surface. This layer prevents oxygen and water from reaching the metal, which slows down the corrosion process.

Other types of corrosion inhibitors include:

* Anodic inhibitors: These inhibitors work by blocking the anodic reaction that occurs during corrosion. * Cathodic inhibitors: These inhibitors work by blocking the cathodic reaction that occurs during corrosion. * Mixed inhibitors: These inhibitors work by blocking both the anodic and cathodic reactions that occur during corrosion.

The selection of the right corrosion inhibitor for a particular application depends on a number of factors, including the type of metal being protected, the environment in which the metal is exposed, and the desired level of protection.

Scale Prevention

Scale is a buildup of mineral deposits that can form on the inside of pipes and other equipment. Scale can restrict flow, reduce efficiency, and even cause equipment failure.

Chemicals are used to prevent scale formation by binding to the minerals and preventing them from forming deposits. There are a variety of different scale inhibitors available, each with its own advantages and disadvantages.

The most common type of scale inhibitor is a chelating agent. These inhibitors work by forming a complex with the metal ions that cause scale to form. This complex prevents the metal ions from reacting with other substances to form scale.

Other types of scale inhibitors include:

* Dispersants: These inhibitors work by breaking up scale deposits and preventing them from agglomerating. * Threshold inhibitors: These inhibitors work by preventing scale crystals from growing to a size where they can form deposits.

The selection of the right scale inhibitor for a particular application depends on a number of factors, including the type of scale being prevented, the environment in which the scale is forming, and the desired level of protection.

Water Treatment

Water is used in a variety of applications in refineries and pipelines. However, water can also contain impurities that can cause problems, such as corrosion, scale formation, and microbial growth.

Chemicals are used to treat water and remove these impurities. Water treatment chemicals include:

* Coagulants: These chemicals work by causing impurities to clump together and form larger particles. * Flocculants: These chemicals work by binding to the clumped impurities and making them heavier. * Precipitants: These chemicals work by causing the impurities to form a solid precipitate that can be removed from the water. * Disinfectants: These chemicals work by killing bacteria and other microorganisms in the water.

The selection of the right water treatment chemicals depends on a number of factors, including the type of impurities present in the water, the desired level of treatment, and the environmental regulations that apply to the discharge of treated water.

Fuel Additives

Fuel additives are chemicals that are added to gasoline, diesel, and other fuels to improve their performance. Fuel additives can improve fuel economy, reduce emissions, and protect engine components.

There are a variety of different fuel additives available, each with its own advantages and disadvantages. The most common type of fuel additive is a detergent. Detergents work by removing deposits from fuel injectors and other engine components.

Other types of fuel additives include:

* Antioxidants: These additives protect fuel from oxidation, which can lead to gum formation and other problems. * Metal deactivators: These additives prevent metals from catalyzing the formation of gum and other deposits. * Lubricity additives: These additives reduce friction between moving engine components.

The selection of the right fuel additives for a particular application depends on a number of factors, including the type of fuel being used, the engine type, and the desired level of performance.

Demulsifiers

Demulsifiers are chemicals that are used to break up emulsions. An emulsion is a mixture of two immiscible liquids, such as oil and water. Demulsifiers work by reducing the interfacial tension between the two liquids, which allows them to separate.

Demulsifiers are used in a variety of applications in refineries and pipelines, including:

* Separating oil from water in produced water * Separating oil from water in crude oil * Separating oil from water in fuel tanks

The selection of the right demulsifier for a particular application depends on a number of factors, including the type of emulsion being broken up, the desired level of separation, and the environmental regulations that apply to the discharge of treated water.

Surfactants

Surfactants are chemicals that reduce the surface tension of liquids. This makes them useful for a variety of applications, including:

* Wetting agents: Surfactants can help liquids to wet surfaces more easily. * Detergents: Surfactants can help to remove dirt and grease from surfaces. * Emulsifiers: Surfactants can help to create emulsions, which are mixtures of two immiscible liquids. * Dispersants: Surfactants can help to disperse solids in liquids.

Surfactants are used in a variety of applications in refineries and pipelines, including:

* Cleaning tanks and equipment * Removing oil from water * Dispersing solids in fuel oil

The selection of the right surfactant for a particular application depends on a number of factors, including the type of liquid being treated, the desired level of performance, and the environmental regulations that apply to the discharge of treated water.

Polymers

Polymers are long-chain molecules that are made up of repeating units. They are used in a variety of applications in refineries and pipelines, including:

* Flow improvers: Polymers can be added to liquids to improve their flow properties. * Viscosity modifiers: Polymers can be added to liquids to increase their viscosity. * Drag reducers: Polymers can be added to liquids to reduce their drag. * Flocculants: Polymers can be used as flocculants to help impurities in water to clump together and form larger particles.

The selection of the right polymer for a particular application depends on a number of factors, including the type of liquid being treated, the desired level of performance, and the environmental regulations that apply to the discharge of treated water.

Chemical Injection

Chemicals are typically injected into refineries and pipelines using chemical injection pumps. These pumps are designed to deliver a controlled amount of chemical to the process fluid.

Chemical injection pumps are available in a variety of sizes and configurations. The type of pump used for a particular application depends on the flow rate, pressure, and viscosity of the chemical being injected.

Chemical Storage and Handling

Chemicals used in refineries and pipelines must be stored and handled properly to ensure safety and environmental protection. Chemicals should be stored in a cool, dry place away from incompatible materials. They should also be stored in containers that are compatible with the chemical and that are properly labeled.

When handling chemicals, it is important to wear appropriate personal protective equipment (PPE). PPE includes gloves

4 out of 5

| Language | : | English |

| File size | : | 6542 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 240 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Text

Text Genre

Genre Reader

Reader Magazine

Magazine Newspaper

Newspaper Shelf

Shelf Bibliography

Bibliography Foreword

Foreword Synopsis

Synopsis Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Classics

Classics Biography

Biography Autobiography

Autobiography Memoir

Memoir Encyclopedia

Encyclopedia Thesaurus

Thesaurus Character

Character Librarian

Librarian Catalog

Catalog Card Catalog

Card Catalog Borrowing

Borrowing Stacks

Stacks Periodicals

Periodicals Scholarly

Scholarly Lending

Lending Academic

Academic Reading Room

Reading Room Rare Books

Rare Books Literacy

Literacy Thesis

Thesis Storytelling

Storytelling Awards

Awards Book Club

Book Club Theory

Theory Andy Adams

Andy Adams Victoria Zigler

Victoria Zigler Robert G Watkins

Robert G Watkins Wilson Ring

Wilson Ring David Martinez

David Martinez William G Roy

William G Roy Susan Kilbride

Susan Kilbride Clark Wilkins

Clark Wilkins Ian Gordon

Ian Gordon William A Cook

William A Cook Harry Altman

Harry Altman Barbara Mervyn

Barbara Mervyn Christopher Day

Christopher Day Kris Neely

Kris Neely Doug Gelbert

Doug Gelbert Emma King

Emma King John J Davenport

John J Davenport Deke Dickerson

Deke Dickerson Pj Ryan

Pj Ryan Flannery O Connor

Flannery O Connor

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Hayden MitchellPragmatic Marketer Spring 2024: Elevate Your Product Management and Marketing...

Hayden MitchellPragmatic Marketer Spring 2024: Elevate Your Product Management and Marketing...

F. Scott FitzgeraldThe Secret Life Of Theater: On The Nature And Function Of Theatrical...

F. Scott FitzgeraldThe Secret Life Of Theater: On The Nature And Function Of Theatrical...

Corey GreenThe Poetic Prose and Haunting Melodies of Alanis Morissette: A Comprehensive...

Corey GreenThe Poetic Prose and Haunting Melodies of Alanis Morissette: A Comprehensive... Dawson ReedFollow ·16.5k

Dawson ReedFollow ·16.5k Edison MitchellFollow ·12.6k

Edison MitchellFollow ·12.6k Cody BlairFollow ·13.2k

Cody BlairFollow ·13.2k Xavier BellFollow ·7.1k

Xavier BellFollow ·7.1k Dan BrownFollow ·7.9k

Dan BrownFollow ·7.9k Hunter MitchellFollow ·12.8k

Hunter MitchellFollow ·12.8k Finn CoxFollow ·14.5k

Finn CoxFollow ·14.5k Pete BlairFollow ·19.1k

Pete BlairFollow ·19.1k

Raymond Parker

Raymond ParkerFully Updated and Revised: A Comprehensive Guide to the...

Welcome to our...

Carter Hayes

Carter HayesUnraveling the Gritty Murder Case that Shocked Edinburgh

A Chilling Crime ...

Bryan Gray

Bryan GrayTurlough Carolan's Enchanting Irish Harp Melodies: A...

Turlough Carolan, the legendary Irish...

Larry Reed

Larry ReedCamper's Guide to Knots and Lashings: A Collection of...

Knots and lashings are essential skills for...

Spencer Powell

Spencer PowellReframing Nonprofit Management: Democracy, Inclusion, and...

The nonprofit sector...

4 out of 5

| Language | : | English |

| File size | : | 6542 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 240 pages |